If we summarize the cohesive hard-to-flow bulk products that are transported around the World, we can have a significant idea of the possibilities which can arrive containerizing part of this traffic.

If we add up the total transport volume of hard-to-flow bulk products such as Aluminum Oxide, Bentonite, Cement, Kaolin, Corn Fluor, Starch, Gypsum, Iron Oxide, Lime, Manganese Oxide, Melamine, Milk Powder, PVC Emulsion, Potash, Soda Ash, Talc, Titanium Dioxide and many more. We can have an idea of the potential market growth that can be achieved by using the Fluidization Liner with containerized transport so unloading may become standardized.

Having the right tools and know-how will permit shippers, logistic operators and importers to handle, transport and deliver hard-to-flow bulk products by containerized transport.

Now let us look over the actual situation of cohesive bulk solid handling and transport: bulk cargo and breakbulk cargo.

Transporting cohesive bulk solids in bulk ships

High volume cohesive bulk solids are usually high-volume commodities which are transported by loading the bulk solids from factory to dump truck and transferring in the ports from bulk truck to ship holds. This process repeats itself at the port of destination, which can even be more complicated as the merchandise must be loaded from dump trucks to silo trucks so it may be loaded up into silos.

This process also exposes Bulk Solids to being contaminated by humidity or other external agents while transferring from one mode of transport to another. Major ports are usually equipped with facilities to handle thousands of tons of bulk solids at a time, although the final mile is usually done by road transport in dump trucks with little protection.

The final process of feeding silos is also complicated and expensive as dumper trucks can unload onto subterranean silos but not into standard vertical silos.

Considering the millions of tons of bulk solids, which are transported all over the World by bulk cargo, we can consider that containerizing even a small percentage of this traffic would be extremely interesting for shipping companies, as bulk transport compensates normal container routes. Raw materials and palletized goods in many cases come from opposite origins.

Break bulk and FIBCs (big bags) as an alternative to bulk transport

Loading in FIBCs on tautliners and transferring the Big Bags into chartered vessel holds is a another way of transporting bulk solids, as the port of origin and the port of destination do not require great facilities.

The whole process is basically filling FIBCs and then transferring them through many modes of transport, until the Big Bag is broken and the goods are returned to bulk mode and loaded into a silo or production line. The Process requires a great amount of handling and therefore the amount of manpower required is very significant, as well as equipment for filling big bags and for unloading them and transferring the goods into the silo.

Handling Process:

Beginning the process means chartering a vessel that can connect the port of loading with the port of loading with the port of unloading. A minimum quantity of produce is needed to optimize contracting a hold or the complete vessel. Therefore, the supply chain is not flexible as great quantities must be transported in comparison with normal container transport.

As the merchandise is transferred from one mode of transport to another by different operators; in the case the merchandise is compromised in any way, the legal consequences must be resolved among the operators and their insurance companies.

Fluidizing liner for flexible logistics at loading cohesive hard-to-flow bulk products

The Fluidizing Liner permits confident handling of high volume cohesive products from shipper to importer, door to door, without transferring the product from different modes of transport. The hard-to-flow bulk products will be unloaded from the liner container into the importers silo with a perfectly controlled process.

The ideal concepts for transport in the minds of any Supply Chain Manager, Export Manager or Logistics Operator are secure, fast, easy, cheap, available and accessible world-wide.

Container transport offers good transit times, pricing, weekly sailings and a global outreach through container shipping lines and inland intermodal connections which are second to no other logistic circuit.

Product protection: the container seal will be installed by the shipper and broken by the importer. There is no transfer of goods involved in this process.

The main concepts in the mind of Factory Quality Control Managers factors are safety and standardized work protocols. Manpower is minimal and moving equipment such as forklifts, hydraulic lifts or similar equipment will not intervene in direct loading and unloading from container liners to and from silos.

Fluidizing liner unloading protocol

The Fluidizing Liner does not require any kind of direct investment apart from positive air and a rotary valve. Easy unloading with a proved Fluidizing System which will be able to unload cohesive bulk solids directly into a silo.

BULK-FLOW’s Fluidizing System is flat and completely embedded into the floor of the fluidizing bulk liners that allows the free discharge flow of the commodity without the obstructions of protruding air hoses typically used in other fluidizing systems. In addition, unlike systems that utilize air hoses, which are frequently dragged during discharge, BULK-FLOW’s flat fluidizing system remains in place from start to finish.

To summarize, standard factory equipment: positive air and a rotary valve together with a tilt container are the equipment needed to implement hard-to-flow bulk products handling, transport and unloading.

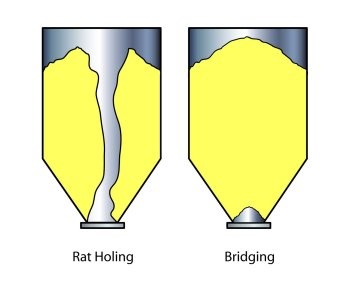

Very cohesive hard-to-flow bulk products demand Fluidization and also Vibration as an auxiliary tool to impede the tendency of caking, bridging and ratholing very common in products such as Soda Ash, Lime or Sodium Sulfate. Ratholing is the main problem at applying fluidization, as tunnels are created by the air flow and therefore diminishing the effect on the mass of the bulk solid.

Vibrators are installed on the exterior wall of the containers and are activated at intervals to break up the mass solid and therefore permit the fluidization to do its job. Therefore, the Process continues to be controlled and automatic.

Conclusion of the case study between bulk, break bulk and containerized liner transport for cohesive and hard-to-flow bulk solids

There are many variables to be studied at implementing one of these modes of transport over the other two, such as port facilities, client’s stock capacity, local transport equipment, distances from the port or train terminal, cost of manpower and local legislations pertaining to road and intermodal transport and a long list of other exponents.

But in any case, the future will transfer a lion’s share of bulk solid transport from bulk and break bulk to containerized liner transport.

The possibility of unloading cohesive bulk solids directly into silos and to clients production lines is extremely simple and cost efficient.

Bulk-Flow is specialized in creating liner solutions for hard-to-flow bulk solids but changing protocols and mindsets is a slow process, but we are here to guide our clients to better their processes by studying each bulk solid and handling process.