Not an easy question to answer

Actually, it is very difficult to coach a person or company on how to choose anything.

Bulk-Flow offers some objective parameters to apply and behaviors to look for before choosing a bulk container liner supplier.

First, start with the end in mind:

- Define as many different alternatives as possible.

- Decide upfront what is the desired result.

The cost effectiveness of the supply chain

There are many other possible objectives to choosing a container bulk liner supplier, like:

- “the humidity barrier must be over a certain level,” or

- “the liner must be made of PE film.”

But if we go down this path, there will be so many variables that not even a 20-page article I could cover everything.

Let’s “stick” to “finding the most cost effective” alternative with the best results available for your supply chain.

To do so, define the most relevant costs for bulk material handling and transporting easy or hard-to-flow products that could be impacted by the container bulk liner.

As previously discussed in the “Three ways to minimize the impact of the packaging on export bulk shipping costs” article, the best option to transport bulk solids of a certain load size through certain distances is a container with the corresponding bulk packaging, or the container bulk liner.

The question is:

From which supplier should you purchase?

Establish your selection criteria

First, consider that every business needs a good quality supplier.

Good products, with good solutions, so you may need to look for the best when making your choice.

If your company depends on having bulk solids sent to long distance destinations, whether in-country or export, you are even more dependent on the quality of the container bulk liners you use. Substandard liners, run the risks of affecting the overall quality of the goods that you deliver or, even worse, risk wasting portions of the bulk solids.

The effects of saving money on the price for the lower-quality bulk liner can result in big losses in the end – for example, loss of customers because you are responsible for selecting the supplier based on the quality of their liners.

It is very important to compare the liners from different suppliers, ask questions about the technologies applied and the reasons why they are made a certain way.

It is equally important to perform tests with the proposed liners.

The end-user should be involved this stage of the process to define the materials used to make the liner, sizes, types and number of sleeves / ports, how the bulkhead is made, and what is the containment of the bulkhead (metal bars, wooden boards or barless, number of bars, etc.)

After requesting proposals and samples to test products, technically compare the liners from the different suppliers considered by including this criteria:

- Get References (user reviews):

In the same way that one should research previous customers’ reports thoroughly when buying a cell phone, new shoes, a new computer or even wine on the internet, the decision maker for the company that is searching for a bulk container liner supplier should check previous users’ reviews. The first criteria to evaluate are what the suppliers’ customers are saying in their reviews and if the supplier in question is in the approved suppliers lists of government(s) and/or large industries. - Find out about the Supplier’s Reliability:

- Delivery Time / Delivery Commitment

Receiving the liners on time (having them ready for use when needed) is basic.

Not having the liner ready when needed is a major flaw that can generate big losses, so this is an important parameter to consider. - Ease to communicate – is there a “hotline”, a sales rep or customer service that can be reached in case problems arise?

- How long has the supplier been in business?

- Delivery Time / Delivery Commitment

- Consider checking your supplier’s finances (public statements, business bureau records, etc.). Credit checks are also a good indicator of how your possible supplier behaves and give you an idea about their financial backup to support the production, delivery, and collection of your future orders.

- Innovation capabilities of the possible suppliers:

Check the number of innovations, patents and new processes proposed by the suppliers.

This is a very important point because it shows the aspiration for excellence, and it is always a good indicator that the liners from the more innovative supplier will improve consistently.

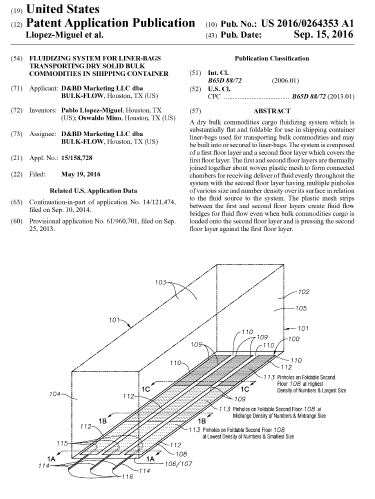

Innovations like the fluidized liner, the barless liners, the single bar liner or the tiltless system from Bulk-Flow are important differentiators that provide much more flexibility and reliability to your process. A supplier that provides all of these alternatives is able to come up with a much better solution than the others. - Collaborative disposition of possible suppliers:

Pick a collaborative supplier that helps solve your problem, not one that only sends you merchandise (the liners).

In other words, choose a supplier that shares its knowledge, like Bulk-Flow does in this blog, and that does not leave your questions unanswered. - Compliance certification:

Make sure that you know about their processes and business practice compliance. - Product value:

The purchaser must be very clear about the abysmal difference between price and value, and what should be included in the a comparison parameters – the VALUE of the product, trumps the price.

Next, the procurement team must list and compare all of their findings (i.e.: in a spreadsheet or with a scorecard system) attributing different weights to each question to create a decision matrix to choose the container bulk liner supplier.

Bulk-Flow advisors are available to help you improve your logistics process and methods to create a much more efficient supply chain that generates greater

profits for your company.

Bulk-Flow specializes in creating innovative liner solutions for all kinds of bulk solids, even hard-to-flow bulk solids.