Thermal Container Liners’ Advantages for Bulk Wine Cargo Shipments

The U.S. wine industry continues to enjoy steady growth in bulk exports around the world. It averages an increase of about 10-15% per year, according to the U.S. Department of Agriculture and published reports like that of RaboResearch Food and Agribusiness. Forecasts from 15 years ago predicted a greater market demand that has been met with increased supply and incredible costs savings every time that wine is transported in bulk – somewhere to the tune of US$142,300,000 in 2010 alone. Thermal container liners can protect loads of bottled wine cargo that could spoil with changing external temperatures during the import/export voyage, thus adding more dollars to cost savings.

Although other ways to transport wine in bulk include reusable stainless-steel tanks (ISO tanks) and Flexitanks (fitted container plastic bags for standard 20’ containers), wine is still transported in ready-to-sell bottles and in casks, for the bottles’ sealed properties that preserve quality, leaving out possible contaminants.

Consider the Costs – Gains and Losses in Bulk Wine Cargo

Certainly, there are added costs to transporting wine in individually packaged bottles in comparison to tanks. Consider the larger volume of wine cargo that can be transported in one bulk shipment versus the smaller amount delivered in bottles to a destination. It all adds up and affects the bottom line. Rabobank calculates that there’s a cost savings of at least US$1.50 per case of wine when it is shipped in bulk and bottled at the destination, instead. Approximately 1.5-2 billion liters of wine are transported in bulk tanks every year – that’s only 10% of all wine shipped in a year.

Another main precaution to take with bulk wine in ISO tanks is that, although they can be temperature controlled and carry up to 26,000 liters of wine, there’s the possibility for cross-contamination if the tanks are not cleaned and sealed properly after each use. This issue spurs from the fact that hazardous and chemical cargo are also shipped in these reusable containers.

Since wine is consumed by humans, all alarms go off at this point. Hence, recent technological advances have generated upgraded versions of Flexitanks made out of polyethylene ethylene vinyl alcohol (EVOH) copolymer that acts as a barrier to keep the wine from exposure to any contaminants that could still be in the container, thus preserving the quality of the wine cargo. These Flexitank bags are used one time and then thrown away which helps eliminate the contamination concern. However, temperature is one property and environmental component that can’t be controlled in Flexitanks. This also means that the wine can oxidize during transportation.

(Google images)

Among wine companies’ priorities for profitability, packaging and moving product quickly are towards the top:

- End-users weigh a considerable portion of the decision whether to purchase a certain wine or not on what the bottle and label look like.

- Wine starts to deteriorate at the time it’s poured into a bottle.

The preference to ship wine in bulk tanks instead of individual bottles could extend the product’s shelf life; however, it also slows down the ability to place it in the marketplace rapidly for end-customers to purchase.

Thermal Container Liner Benefits for Bottled Wine in Bulk

A full maritime container carrying bulk wine cargo in bottles can transport a load of up to 13,000 liters of this commodity. Despite the appeal and advantages to carry larger quantities of wine in bulk in ISO tanks and Flexitanks, the hazards of cross-contamination and spoilage due to temperature changes are very real and include the potential of a substantial profit loss. Yes, it’s true that transporting wine in bulk in bottles adds costs for extra packaging and special handling because of the fragile glass, but the speed at which it can be taken from containers to the market is worth it – especially if it has retained great food grade quality. This is part of what makes it so convenient for small and large wine vineyards and producers, distributors/brokers, and buyers and sellers. So that only leaves the issue of exposure to temperature changes unaddressed.

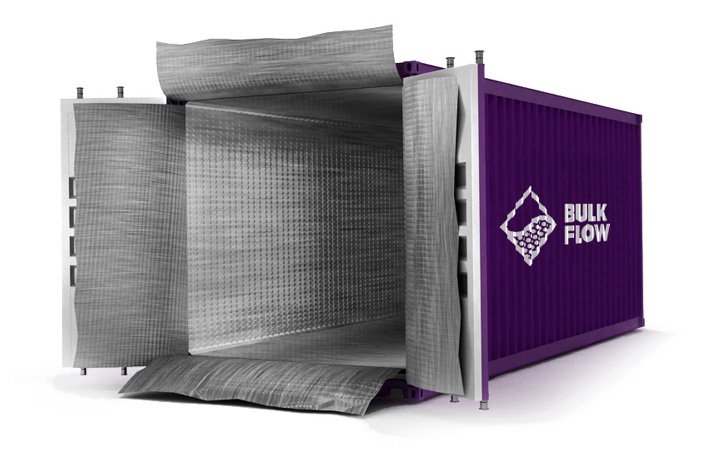

Thermal container liners provide a solution thanks to the following features:

- They are made from a multi-layer composite material that may include aluminum foil, HDPE film, PET, bubble wrap, and/or other materials.

- High temperatures within a container can cause the wine to heat up. Likewise, when temperatures reach a certain level, the wine may over-ferment and release corrosive gases. Thermal container liners prevent this crisis by shielding the bottled wine cargo from radiant heat and UV light.

- Thermal container liners are made from flame-retardant material to reduce flammability (perhaps for the packaging) and prevent damage to the wine cargo.

- Temperature-sensitive wine may sustain moisture and/or mold damage when temperature changes cause condensation to form inside of the container. Thermal liners help prevent significant changes in the internal temperature of the container, to reduce the risk of damage.

Bulk-Flow’s thermal radiant barrier liners protect from an extreme heat average – 10°C (-18°F) or from an extreme cold average of +8°C (+14°F). It hangs in marine shipping containers and allows forklift traffic. Once loaded, it is sealed off on the door side to protect the cargo from extreme temperatures, humidity and fire. The aluminum foil reflects 97% of the radiant heat, and the fully enclosed liner prevents the air from spreading the heat by convection.

Bulk-Flow’s thermal reflective insulation liners protect from an – 24.5°C (-44°F) or from an extreme cold average of +20°C (+36°F). Its aluminum double-sided foil and an internal layer of air bubbles reduce heat transfer by radiation as the primary mode, and by conduction and convection as secondary.

In addition, thermal reflective insulation liners can be used in marine shipping containers and allows forklift traffic. Once loaded, it is sealed off on the door side to protect the cargo from extreme temperatures, humidity and fire.