Sometimes the challenge of loading or unloading bulk solid products is not to break the “grains” when using bulk throwers, or not throwing it in high velocity, or even to keep fines from scaping the containment area, but, one of the most common problems we face is to move and accommodate the “hard to flow” bulk solids, what is, even being a well known phenomena, not provided with many solutions.

After the container liner bag technologies have been developed (one of the bulk packaging technologies), and well accepted in the logistics markets, the bulk solids carrying companies started to try and test new uses for these new technologies.

What the Container Liner Bags brought then?

It brought an important milestone on the bulk handling processes, increasing the supply chain efficiency so the profits of the company.

Once it was very clear to most of the logistics players that the costs to carry bulk solids into containers was lower than using big bags to do it (the lower costs come from not using expensive operations to load, unload or transload from and/or to big bags, plus the cost of the individual big bags), no matter if the big bags were arranged inside containers or simply piled up inside general cargo bays, trading them to container liner bags to carry bulk solids started to grow up and become more and more the industry trend.

A “hard to solve” problem:

Many of the products that are carried in containers using liner bags are what can be called as hard-to-flow bulk solids.

As anyone can expect, there are many different definitions, technical or “philosophical” ones, for a hard-to- flow bulk solids product.

One can define this flowing difficulty by watching it to flow over a tilted flat table, and observe the low speed plus the need of a high angle that to start this flow, or, more accurately, we could define the flow difficulty by means of some physical parameters and mathematical equations drawn from laboratory tests and observations, that mostly will describe the low velocity flow behavior of this kind of product.

The result of not flowing easily is sometimes consolidating, bridging (in hopper flows) or just not moving easily when using the gravity forces to move it (tilting the bottom plane, silo hopper, etc.), resulting in obstructions, bumps, etc., that will slow down the movement. Most of the flowability studies try to define the hard-to-flow products through mathematical – physical measurable characteristics that showed to be significant in the capacity of a bulk solid to flow.

How to define what is a “hard-to-flow” product?

One of the characteristics of this kind of bulk solids is the cohesion between its particles coming from several different sources, from electrostatic attraction to hygroscopic behaviors or even capillarity behaviors, that, at the end, results in high angles of repose, making hard to distribute evenly the products inside a pit or a container.

The difficulty to flow is normally related to the size of particle, cohesion forces between particles and/or electrostatic electricity generation / dissipation capacities, hygroscopic or capillarity capacities, friction forces between the bulk solid and the walls / floor, moisture content (that will affect the cohesion forces between particles) as well as particles form inducing the particles repose arrangement, thus the bulk density.

Why the idea of fluidization of the product though

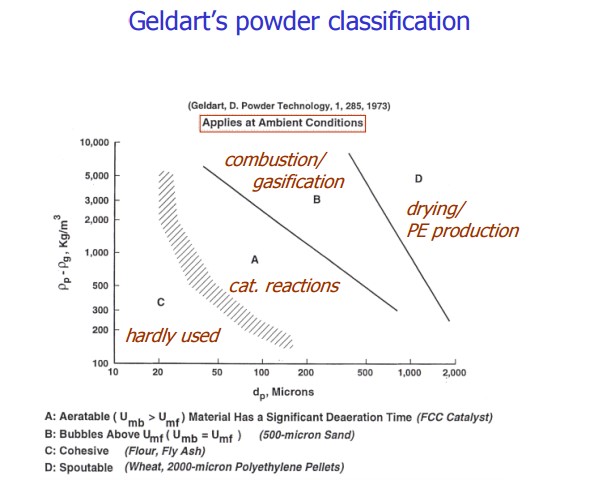

It is somehow common to see the hard-to- flow characteristics of a bulk solid associated with the fluidization regime parameters, mostly known from the Geldart (Geldart, 1973) fluidization description, that relates the density differences (apparent and solid densities) with the particle sizes to define the fluidization ability of a bulk solid.

Where:

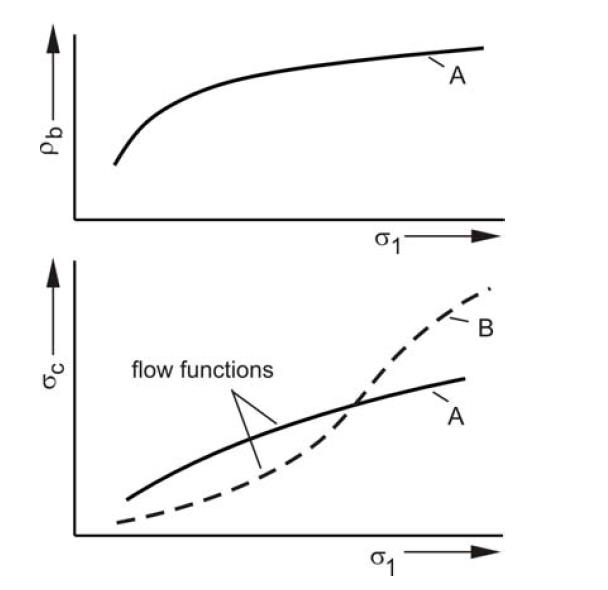

- ρb = Bulk Density

- σc = Unconfined Yield Strength

- σ1 = Consolidation Stress

A long time ago it was noted that any particulate or bulk solid material would assume a flow behavior very similar to a fluid when subjected to the passage of some gas across it, creating the so called fluidization. As even the hard-to-flow bulk solids can be fluidized, changing their flowability characteristics for better, this, the fluidization was one of the first good answers to improve the flowability of the hard-to-flow materials and so improve the distribution of it during the loading operations of a container.

Hard-to-flow products load operations

Most of the hard-to-flow materials are loaded in one of the following ways into a container, lined with a container liner bag, by means of several different bulk container loading equipment and processes as described below:

- Belt Thrower Conveyor: Either high (throwers) or low velocity types, cleated or slick belts, the belt conveyors are very important loading mechanisms, no matter if for containers or bulk carriers (train cars, bulk carrier ships, etc.). It is widely used to carry all kinds of bulk material, easy or hard to flow.

The importance of this kind of conveyor is closely related to the capacity of loading a container without needing to reverse tilt it, and to be able to transload products without the need to have it in a high silo.

This loading process needs attention from the operator in order to avoid forming product piles resulting in poor distribution inside the container. - Silo – Hopper: This is the most used way to load a container with resins and other kinds of granulated matters such as the PET, Polypropylene, Polystyrene, PVC and other kinds of solid granulated resins, Carbon Black, granulated acids such as the Purified Terephthalic Acid (PTA) or even a much harder to flow material such as Glyphosate.

Most of those products are stored in silos and then transferred to containers through the use of hoppers and or pneumatic conveying systems.

Sometimes the containers need to be tilted up in order to be filled to its maximum (approximately 80% of the total container volume for a 20ft container). - Pneumatic conveying: This is usually the way to better distribute the product inside the container, but it needs attention from the operator if the product is a hard-to-flow not to form high piles of product making a poor distribution / occupation of the container.

When the container is loaded using a belt or a pneumatic conveying system, the possibilities of a poor distribution are high, so, a very simple solution for improving the product distribution inside the container is to fluidize it from the bottom.

This is the solution that Bulk-Flow created to maximize the use of the containers for our customers.

What Bulk-Flow offers to reduce the difficulties in loading hard-to-flow products

The use of a fluidizing bed in the bottom allows the hard-to-flow materials to settle more evenly during the loading operation, avoiding the formation of piles, increasing the usable capacity of the container, plus reducing the labor, loading time, etc.

If we compare a container filled with a hard-to-flow bulk solid product using one of our Fluidizing Liners, with a container not using it, there will already be a significant cost difference per use, but when compared to the old big bags, piled over pallets, moved with fork trucks, there is a much bigger difference in the man-hour need plus the container capacity, not to talk about the cost difference between all the big bags and the single liner bag.

Contact us on LinkedIn, Facebook or Twitter, schedule a conference call or a conversation, we will provide you with our free assessment.