What is Soybean Meal?

Soybeans are crushed and pressed to produce soybean meal and then taken through a chemical process with hexane to extract oil, resulting in a bulk solid, powder-like product that contains fiber and proteins.

While the biggest amount of vegetable oil produced in the world is extracted from palm (123 million metric tons per year), soybean is the second most used vegetable to extract oil. Soybean meal generates this high-protein content byproduct the most.

Even though maize is the top field crop in the U.S., measures more than twice the size of any other crop, and it’s the raw material for corn sweeteners (i.e., high fructose corn syrup) and ethanol fuel, soybean is currently one of the most important oilseeds for extracting food protein and oil products in America.

How are Soybeans processed?

Oil is essentially extracted from soybeans as follows:

- First, soybeans are cleaned and dehulled.

- Then, they’re sent through cracking rolls that reduce them into particles that are a small fraction of the original size of the beans.

- The fragments are sieve-graded and the hulls are separated from the meat with a vacuum.

- The hulls are sent to be toasted and ground to be added to animal feed.

- The portion that was cleaned and cracked resulting in meats goes through a conditioning-cooking process where the temperature is raised up to 170.6 °Fto keep the moisture content between 9 and 12 % (10%, on average).

- After the conditioning process, the resulting particles are flaked with flaking rolls to thicken them between 0.127 to 0.254 mm. This guarantees that the cell walls are broken down to increase the surface area of the particles, improving the efficiency during extraction.

- The processed, conditioned, flaked product is soaked in a solvent. Normally, the solvent is hexane, but there are other extraction processes to separate the oil from the flakes and form a mixed, highly turbid fluid called micella.

- The oil will be recovered from the micella through thermal separation and then refined.

- The resulting flakes that are spent after this process, will be dissolved in thermal processes to remove any hexane residue.

- The cleaned and dissolved flakes will be processed to become the soybean meal.

The use of soybean oil in enormous quantities worldwide, greater in some places than others, makes it one of the most transported vegetable products / by-products nowadays. Soybean meal also has a significant place in the logistics chains.

How big is the market?

Approximately 90 million acres of crop land is used in the U.S. just for soybean production, yielding 117 million metric tons in the 2017/2018 harvest season. More than 330 million metric tons (MmT) of soybeans are produced worldwide every year. From these 330 million metric tons, approximately 70.3 MmT of oil and 235.6 MmT of soybean meal are extracted.

Soybean meal is widely used to enrich animal food, while the texturized protein TVP, or protein concentrates derived from the soybean meal, are also used for human nutrition.

Although soybean crop areas are well scattered all over the world the processing plants can’t be for better efficiency.

Because processing needs to be centralized to some plants and some by-products are more used in some place than in others, there is a crucial need for transportation of the soybean meal.

Some details about the physical characteristics of Soybean Meal

Like most bulk solid materials, soybean meal has the following characteristics with big physical / chemical variances:

- About 70% of the particles fall into what is considered as the medium to fine range, with particles sizes between 0.59 and 1.20 mm. The particle size distribution reveals a normal or log-normal distribution resulting in a mass diameter means between 0.785 to 0.832.

- The apparent density is very sensitive considering the temperature, moisture content, ambient relative humidity, as well as the protein content.

- The moisture content affects the angle of repose after a power function. The same happens with the density, but after a different function.

- As the other factors have more scattered property variations the apparent densities of solvent-extracted soybean meal range from 545-577 kg/m³ for a 41% protein meal, to 561- 609 kg/m³ for a 44% protein content meal, or even 657-673 kg/m³ when it contains 50% protein. So, consider that the apparent density is between 545 and 673 kg/m³, depending on the protein content.

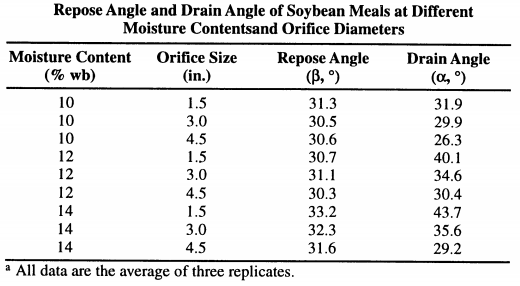

- The repose angle is not as dependent on the protein content as the apparent density. Still, it varies significantly from 30.3° to 33.2° while the drain angle has a much wider range from 26.3° to 43.7°. Some laboratory reports show repose angles up to 35°.

The following table from Physical Properties of Soybean Meal – YUJIE WANG, 2 3 DO SUP CHUNG and CHARLES K. SPILLMAN shows the variation of the angle of repose as a function of the moisture content:

Analyzing the relationship between the angle of repose and bulk density, it can be determined that, as the soybean meal has a medium density (between 0.545 and 0.675) and a repose angle of less than 35 degrees, that this product is most likely to be a non-hard-to-flow bulk solid. This is true as long as the moisture or the protein content doesn’t affect it and makes it hard-to-flow, which would be unusual, so this makes things easier on the handling end.

How is the Soybean Meal transported?

First, look at the two tables below:

Table 1

| Soybean Meal Production 2017 (X 1,000 metric tons) | ||

|---|---|---|

| Producer rank | Country | 1,000 metric ton |

| 1 | China | 75,240 |

| 2 | United States | 41,821 |

| 3 | Argentina | 33,470 |

| 4 | Brazil | 32,500 |

| 5 | EU-27 | 11,455 |

| 6 | India | 7,015 |

| 7 | Russian Federation | 3,743 |

| 8 | Mexico | 3,730 |

| 9 | Paraguay | 2,905 |

| 10 | Egypt | 2,000 |

Table 2

| Soybean Oilseed production 2017 (X 1,000 metric tons) | ||

|---|---|---|

| Producer rank | Country | 1,000 metric ton |

| 1 | United States | 119,518 |

| 2 | Brazil | 112,000 |

| 3 | Argentina | 54,000 |

| 4 | China | 14,200 |

| 5 | India | 9,500 |

| 6 | Paraguay | 9,200 |

| 7 | Canada | 8,000 |

| 8 | Ukraine | 3,890 |

| 9 | Russian Federation | 3,500 |

| 10 | Bolivia | 2,600 |

From the tables above, one can easily depict that a lot of soybeans and soybean meal is moved from place to place. The soybeans arrive in tanker trucks or tanker train cars and are transferred to a storage facility to then be moved in big bulk carriers.

The soybean meal, on the other hand, has moisture content issues that make the bulk carriers’ operation more expensive and difficult, opening a window for container liners.

Bulk-Flow has special liners to carry materials with moisture hazards and can also design customized liners for specific customer needs.

The containers can be loaded at the processing facilities and unloaded at the final usage point, and the containers can be used as intermediary storage.

Approximately 45% (106 million metric tons per year) of the soybean meal produced is sent to a different country from where it originated. Out of this 45%, approximately 50% (53 million metric tons) should easily and more efficiently be carried in containers.